Institutional investors should evaluate both methods to gain a more holistic understanding of a company’s production costs and profitability. This information is crucial for making informed decisions regarding potential investments and assessing the competitive landscape in the industry. The term “production costs” is used to denote the costs a business encounters when creating a product or delivering a service that ultimately generates revenue. Essentially, production costs include all expenses related to manufacturing or providing a good or service that results in income for the company. To be considered a production cost, an expense must directly contribute towards generating revenue.

Case Study: Production Cost Analysis in the Oil Industry

Understanding product cost is essential for setting prices, managing budgets, and making strategic decisions. The budget includes every cost related to the production process other than costs related to direct material and direct labor. The final costs determined as per the overhead budget are not capitalized under the balance sheet but expensed in the income statement as cost of goods sold. These costs include materials, labor, production supplies and factory overhead. product costs consist of The cost of the labor required to deliver a service to a customer is also considered a product cost. Product costs related to services should include things like compensation, payroll taxes and employee benefits.

FAQs about Understanding Production Costs

While product costs are directly tied to the creation and development of a software product or technology solution. Period costs are the expenses that a company incurs during a specific accounting period but aren’t directly related to the product’s development. If production costs varied between $20 and $50 per barrel, then a cash-negative situation would occur for producers with steep production costs. These companies could choose to stop production until sales prices returned to profitable levels. Production costs, which are also known as product costs, are incurred by a business when it manufactures a product or provides a service. The management of Raymond’s has estimated its costs to direct material, direct labor, and factory overhead costs.

Product Cost in Operations Management

- The software development lifecycle is time-consuming, and you may face obstacles that could lengthen your timeline.

- The direct labor costs for Dinosaur Vinyl to complete Job MAC001 occur in the production and finishing departments.

- A well-thought-out pricing strategy that considers production costs can lead to optimal profitability while also appealing to consumers.

- Analyzing production costs enables investors to evaluate the efficiency of a business and assess its competitive advantages or disadvantages in the market.

In the latter case, product cost should include all costs related to a service, such as compensation, payroll taxes, and employee benefits. With a solid financial plan in place, you can identify which components are driving up your product costs and adjust accordingly. Calculating product costs can be a difficult task, especially when it comes to determining the development costs of SaaS. The most crucial step of the whole budgeting process is determining the overall and expected product cost per unit (shirt). Product costs are costs necessary to manufacture a product, while period costs are non-manufacturing costs that are expensed within an accounting period. If the product cost is lower than the industry average, it suggests that the business is operating efficiently.

This not only helps you determine the next project to prioritize but also maximizes your profits. Product cost is a practical concept that is used in a variety of industries and contexts. Knowing the true costs of development can help you determine what features to build, whether for an MVP or for your next major update. The software development lifecycle is time-consuming, and you may face obstacles that could lengthen your timeline.

- In the electronics industry, product cost includes the cost of components (such as chips and circuit boards), labor (such as assembly and testing), and overheads (such as research and development).

- More specifically, production costs are the direct and indirect expenses attributable to a company making a product or furnishing a service.

- It refers to the total expenditure incurred in creating a product, including the cost of materials, labor, and overheads.

- As institutional investors, understanding the intricacies of production costs plays a crucial role in evaluating a company’s financial health and overall performance.

For example, if Company A is a toy manufacturer, an example of a direct material cost would be the plastic used to make the toys. Profitability depends on various factors, including revenue and operational efficiency. While high product costs can impact margins, a company can still be profitable through effective pricing, cost management, and increased sales. Do you know of a restaurant that was doing really well until it moved into a larger space? Often this happens because the owners thought their profits could handle the costs of the increased space.

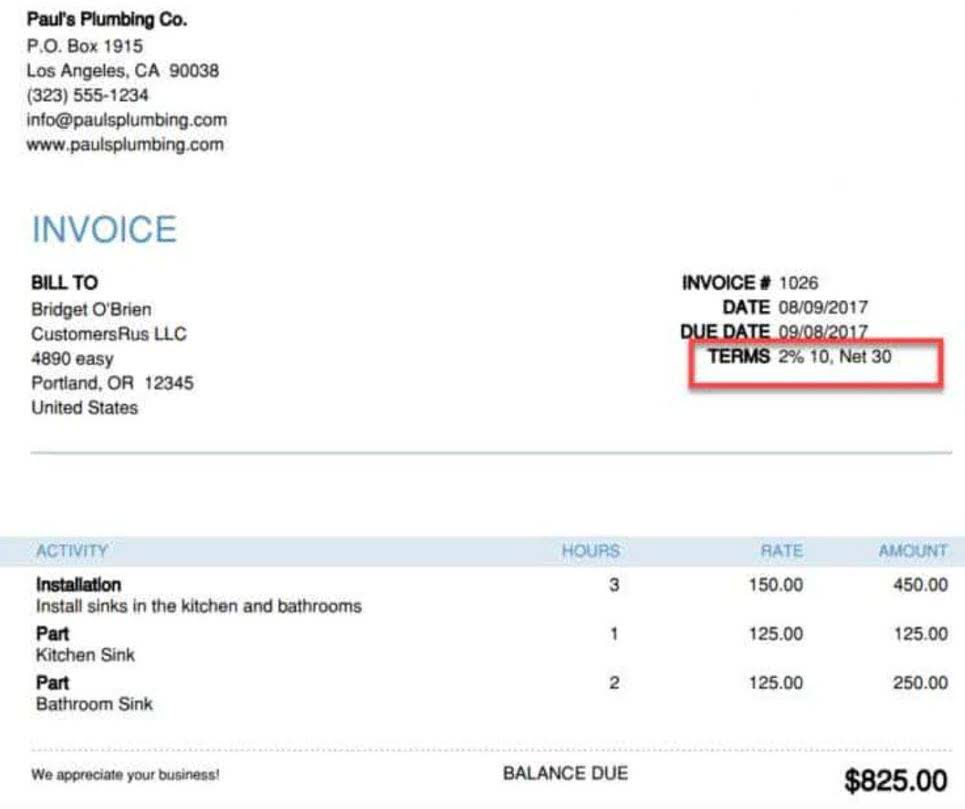

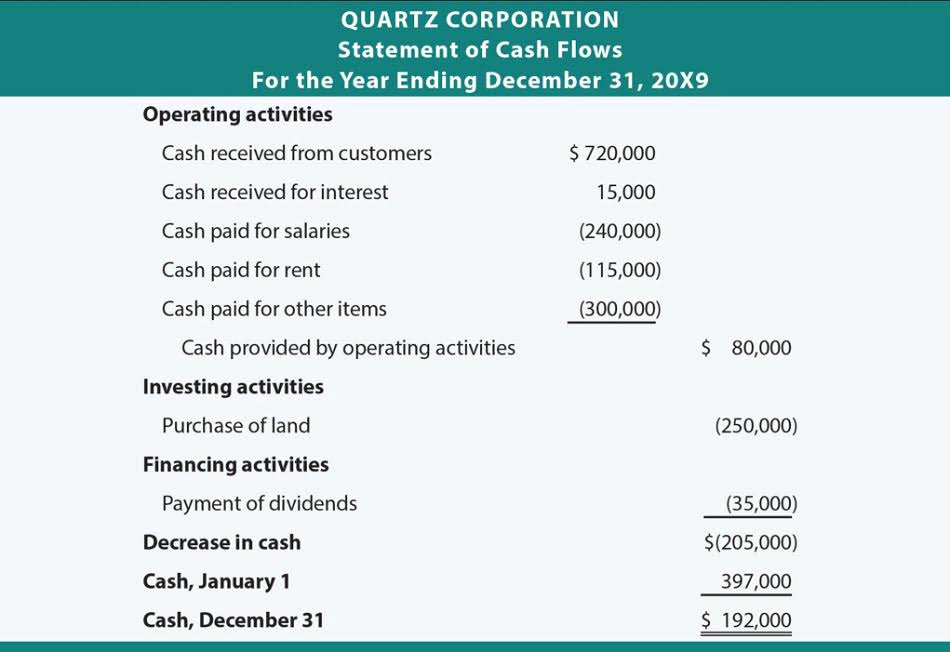

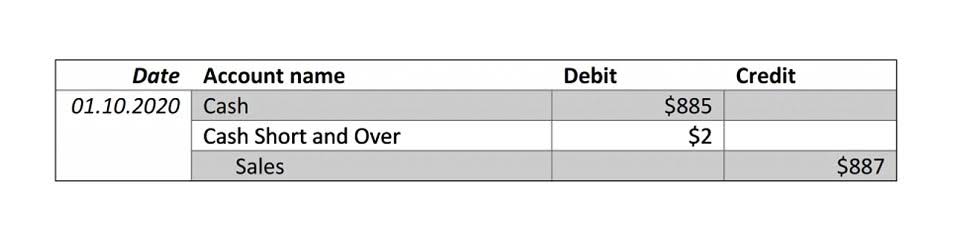

The income statement illustrates revenues and expenses over a specific period, revealing the relationship between sales and operating expenses. petty cash Fixed costs are shown as line items in the income statement, while variable costs vary depending on the quantity produced. Inaccurate reporting of product costs can lead to incorrect pricing, impacting profit margins. It may also result in misinformed business decisions and challenges in assessing the company’s financial health. Some items are more difficult to measure per unit, such as adhesives and other materials not directly traceable to the final product. Their costs are assigned to the product as part of manufacturing overhead as indirect materials.

Example #1 – Direct Material Purchase Budget

Examples include raw materials and the energy consumed during manufacturing processes. Production costs can be calculated using different accounting methods like absorption costing or variable costing. Understanding these methods is crucial for institutional investors as they help evaluate a company’s financial health and profitability.

- Inaccurate reporting of product costs can lead to incorrect pricing, impacting profit margins.

- In conclusion, production costs are a vital aspect of finance and investment analysis as they provide essential information about a company’s profitability, operational efficiency, and financial health.

- Consider the direct raw material to be just fabric, while the requirements of the other two materials cannot be directly tracked and are hence considered indirect.

- Customer research may be the most important step in building and maintaining any product.

- Production costs are essential for businesses generating revenue through manufacturing or providing services, but they can be complex and multifaceted.

The difference between the product cost and the selling price is the gross profit margin. For example, employees may fill out time tickets that include job numbers and time per job, or workers may scan bar codes of specific jobs when they begin a job task. Please note that in the employee time tickets that are displayed, each employee worked on more than one job. At this stage, the completed products QuickBooks Accountant are transferred into the finished goods inventory account. When the product is sold, the costs move from the finished goods inventory into the cost of goods sold.